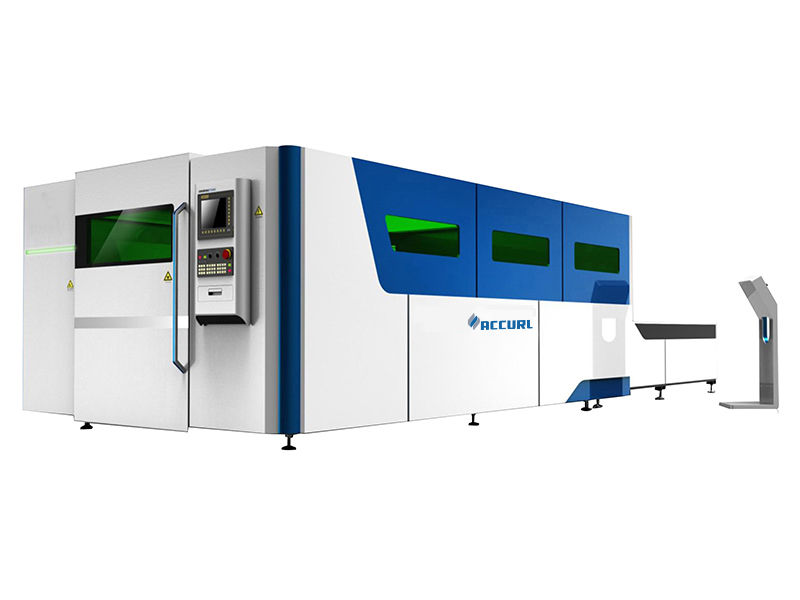

Fiber laser cutting machine features

♦The double rack and pinion driving system and imported open-type CNC system enable high processing accuracy and high working efficiency during high speed cutting.

♦ Standard collocation of 500W fiber laser generator and optional 500W 750w, 1000W 2000W IPG or Raycus or Nlight fiber laser generator ensures low operation and maintenance cost.

♦Open structure is easy and convenient for material uploading and unloading.Drawer collecting device makes receiving materials more convenient.

♦Aiming at high speed cutting, we design and manufacture strengthened welded machine body after 2 times of aging process which ensures long-term accuracy and stability of performance.

♦Standard collocation of dual-pressure gas control system of 3 gas sources (high pressure air, nitrogen, oxygen) meets the processing requirement of all kinds of materials. Easy operation and low cost.

♦Standard collocation of automatic nesting software (including material management and optimized processing technology) and database of process parameters is provided for easy operation and simple management.

Rask informasjon

Bruksområde: Laserskjæring

Tilstand: Ny

Lasertype: Fiberlaser

Brukbart materiale: metall

Skjære tykkelse: materialer

Skjæreområde: 1500 * 3000mm

Klippehastighet: 0-40000mm / min

CNC eller ikke: Ja

Kjølemodus: Vannkjøling

Kontrollprogramvare: Cypcut

Grafisk format som støttes: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Sertifisering: CE, ISO

Service som tilbys etter salg: Ingeniører tilgjengelig for serviceutstyr i utlandet

Product name: XTLASER 500W1000W 2000W 3000W fiber laser cutting machine price

Laserkraft: 2000W

Nøkkelord: Fiber Laser Cutting Machiens

Type: Lasermaskinering

Funksjon: Skjæring av metallmaterialer

Arbeidsområde: 1500mmX3000mm

Skjærematerialer: Rustfritt stål karbonstål Etc (Metal Laser Cutting Machine)

Strømforsyning: 380V / 50 HZ

Driving system: Japan Yaskawa Servo Motor

Kontrollsystem: CNC Prpfession Control System

Lasertype | Fiberlaser |

Laser merke | IPG / Raycus |

Laserkraft | 500W (750W / 1000W / 2000W valgfritt) |

Arbeidsplass | 1500mmX3000mm 1300x2500mm Optional |

Arbeidsbord | Fast arbeidsbord |

Kontrollsystem | PMAC servostyring med full lukket sløyfe |

Kjøremodus | Dobbel girkjøring |

Tomgang / behandlingshastighet | 72m / min / 36m / min |

Posisjonsnøyaktighet | 0.05mm |

Beskyttelsessystem | Kapslingsbeskyttelse |

Laserhode | Precitec / Laser Mech / XT Laser |

Strømforsyning | AC220V ± 5% 50 / 60Hz / AC380V ± 5% 50 / 60Hz |

Total kraft | 7KW~11KW |

Gulvplass | 5,6mX3,2m (fast bord) |

Standard samlokalisering | Metal nesting software, dual-pressure gas route of 3 kind gas sources, dynamic focus |

programvare | CutMax Laser Cutting Software eller PA8000 programvare, Metal Nesting Software |

Støttet format | PLT, DXF, BMP, AI, DST, DWG, etc. |

1) Fiberlaserskjæring er den raskeste prosessen for tynne metallplater.

2) En "clean cut" overflatekvalitet oppnås.

3) Reflekterende materialer som aluminium, kobber og messing kan enkelt kuttes.

4) Deleprosesskostnadene er svært lave.

5) Lite eller ingen vedlikeholdskostnader.

6) Kostnaden for forbruksdeler er lav. De eneste delene som må skiftes er dyser, keramikk og beskyttelsesglass over lengre perioder. Det er ingen andre forbrukskostnader.

7) Resonatorens levetid er over 100 000 arbeidstimer.

Produkt applikasjon

1. Fremstilling av metallplater

2. Elektrisk skap

3. Heis

4. Bildeler

5. Luftfart og romfart

6. Lyslamper

7. Metall håndverk og dekorasjon

8. Maskinvareverktøy

9. Reklame

10. Furniture

11. Kjøkkenutstyr

12. Treningsutstyr

13. Medisinsk utstyr

14. Landbruks- og skogbruksmaskiner

Fiber Laser Generator | YAG Lamp Pump Laser Generator | CO2 RF Metal Laser Tube | |

Makt | 500W/750W/1000W/2000W/3000W | 500W/650W/850W | 300W/500W |

Fordeler | Excellent laser beam quality, high cutting precision, high cutting speed, high efficient photoelectric conversion rate, low use-cost and maintenance cost, easy operation and convenient maintenance | Compared with fiber laser generator and CO2 RF metal laser tube of the same power, it has lower price, thicker material cutting ability, wider application field and lower one-time investment. | It can cut metal sheets and non-metal materials. Wider range of applicable materials. Adjustable output power. Maintenance free. Easy to operate and convenient to use. |

Gjeldende materialer | All kinds of metal sheets and pipes | All kinds of metal sheets and pipes | All kinds of metal sheets and other nonmetal materials |

Gjeldende industri | Sheet metal, hardware, watches, metal art craft works, etc. | Sheet metal, kitchenware, metal letters and accessories & hardware, etc. | Sheet metal, advertising, furniture and models, etc. |