produktbeskrivelse

Product Application:

Furniture ,Medical Device,Fitness Equipment,Oil Exploration,Display Shelf,Farm Machinery,Bridge,Boating,Structure Parts.

Applicable type for tube:

Specially for round,square,rectangular,oval,waist round tube and other metal pipes

Gjeldende materiale:

Carbon Steel, Stainless Steel, Aluminum, Brass,Copper,Galvanized Steel.

Automatic Bundle Loader Steel Square Pipe Making Machine | |||

Pipe type | round, square, rectangular, oval, OB-type, C-type, D-type, triangle, etc (standard),Angle steel, channel steel, H-shape steel, L-shape steel, etc (option) | ||

Pipe length | 6000mm | ||

Pipe size | Φ20-200mm | ||

Gjenta nøyaktighet | ± 0,03 mm | ||

Posisjonsnøyaktighet | ± 0.05mm | ||

Fiber laser source | 1000w/1200w/2000w/2500w/3000w | ||

Posisjonshastighet | Max 90m/min | ||

Chuck rotate speed | Max 105r/min | ||

Akselerasjon | 1.2g | ||

Cut Acceleration | 1g | ||

Bundle size | 800mm*800mm*6000mm | ||

Bundle weight | Max 2500kg | ||

Elektrisk strømforsyning | AC380V 50/60Hz 3PH | ||

Hovedtrekkene

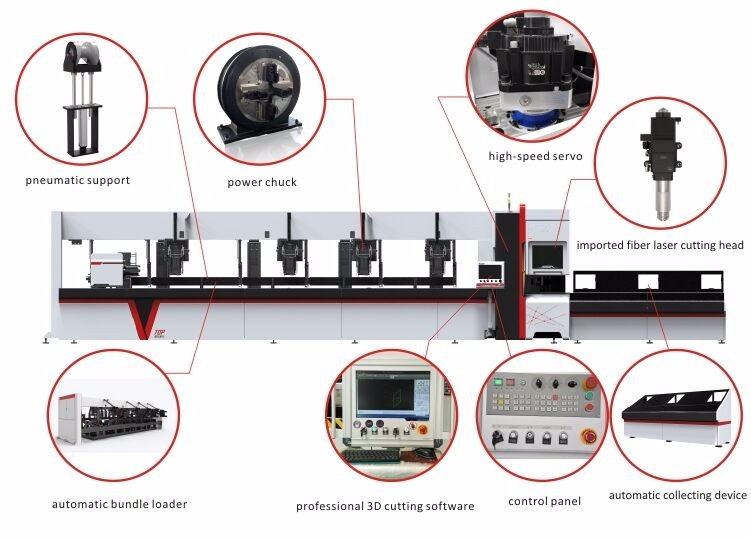

AUTOMATIC BUNDLE LOADER SYSTEM

1,Round pipe, rectangular pipe and other pipes can be fully automated loading, without human intervention. Other shapes pipe can be semi-automatic feeding artificially

2,Max loading bundle 800x800mm

3,Max loading bundle weight 2500kg

4,The total feed manipulator with frame and strand width control transport links in 2200mm, total height control in 2300mm, maximum height of not more than 2500mm. So overall into containers

5,The tape support frame for easy removal

6,Feeding robot body with a chain conveyor link structure integrated design, easy to debug transport

7,The pneumatic system components used AirTAC or other more high-end brand, PLC control, sensors and other selected Omron, Schneider and other well-known brands. Ensure the stability of the system and export standard

Detaljert

Maskindeler

Name: Automatic loading mechanism

1.The total feed manipulator with frame and strand width control transport links in 2200mm, total height control in 2300mm, maximum height of not more than 2500mm. So overall into containers

2.Feeding robot body with a chain conveyor link structure integrated design, easy to debug transport

Maskindeler

Navn: Automatisk innsamlingsenhet

1. Automatisk løftestøtte, motta rør og skrap i kurven

2.Visual skala støtte kan justere støtte diameter raskt i henhold til rørdiameter

3.Visual skalajusterbar støtte løfteinnretning sparer matetid, sikrer konsentrisitet, forhindrer sving i røret

Hovedtrekkene

Name: Power chuck

1.Chuck ved å endre gassbanen, den vanlige chaw-koblingen med fire kjever, optimalisering Cheng-slag power chuck dobbeltvirkende.

2. Å kutte forskjellige diametre, formen på røret i reiseområdet (bilateralt slag 80 mm), ingen grunn til å justere kjeven enkelt oppsett og sentrert.

3.easy switching of different diameters, a substantial saving setup time..

Maskindeler

Name: Pneumatic support

The cutting of pipes of different diameters, by adjustable support system to quickly and accurately find concentricity pipe and claw, to achieve rapid feeding, care feeding purposes, saving setup time cut-out.You can assist chuck support, reducing the swing pipe..

Hovedtrekkene

Name: Integration bed

1. Som en hel plate sveiset seng, hele lengden på 8 meter.

2. Integrasjonsseng kan bedre sikre konsentrisitet av utstyr, vertikal, presisjonsinstallasjon raskt og effektivt.

3.The whole structure is compact precision

Rask informasjon

Tilstand: Ny

Lasertype: Fiberlaser

Brukbart materiale: metall

Cutting Thickness: Depends on power source

Skjæreområde: rørlengde 6m, 8m; rørdiameter 20-300mm

Cutting Speed: depending on materials and fiber power

CNC eller ikke: Ja

Kjølemodus: Vannkjøling

Kontrollprogramvare: Cypcut

Grafisk format som støttes: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Opprinnelsessted: Anhui, Kina (fastlandet)

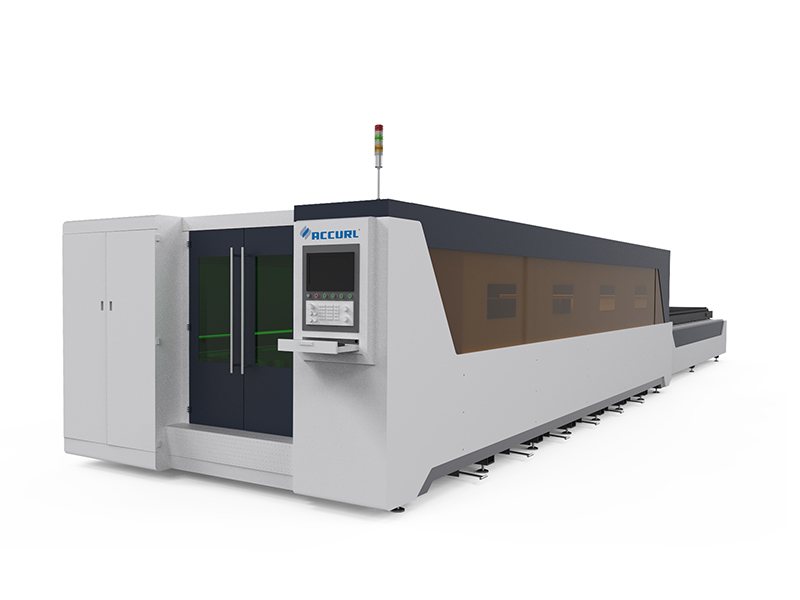

Merkenavn: ACCURL

Sertifisering: CE

Service som tilbys etter salg: Ingeniører tilgjengelig for serviceutstyr i utlandet

Model: P2060A

Repeat position accuracy: ±0.03mm

Position accuracy: ±0.05mm

Fiber laser source: 1000w/1200w/2000w/2500w/3000w

Position speed: Max 90m/min

Acceleration: 1.2g

Electric power supply: AC380V 50/60Hz 3PH