produktbeskrivelse

Laserskjæremaskin i fibermetall

1. Lav pris og strømforbruket er 0,5-1,5kw/t; Kunden kan kutte alle typer metallplater ved å blåse luft;

2. Høy ytelse. Importerte den originale pakkede fiberlaseren, med stabil ytelse og levetiden er over 100 000 timer;

3. Høy hastighet og effektivitet, hastigheten på å kutte metallplater nær titalls meter;

4. Laseren vedlikeholdsfri;

5. Skjærkanten ser perfekt ut og utseendet er glatt og vakkert;

6. Importert overføringsmekanisme og servomotor, og høy skjærenøyaktighet;

7. Dedikert programvare gjør det mulig å designe eller behandle grafikk eller tekst umiddelbart. Fleksibel og enkel betjening.

Parameter av Laserskjæremaskin i fibermetall

| Laserkraft | 500W | |

| Laserkilde | Raycus eller IPG laserfiberlaserkilde | |

| Lasertype | Importert fiberlaser eller toppmerke Kina fiberlaser | |

| Laserteknologi | Tysklands teknologi | |

| XYZ Arbeidsområde | 2500*1300 | 3000*1500 |

| Maks. Kuttetykkelse (CS) | 1 mm - 5 mm | |

| Maks. Klippehastighet | 5-15 meter / min (opptil materialer) | |

| Maks. Plasseringshastighet | 60m / min | |

| Laser bølgelengde | 1070nm | |

| Minimum linjebredde | ≤0.1mm | |

| Plasseringspresisjon | ≤ ± 0,05 mm | |

| Omplasseringspresisjon | ± 0,02 mm | |

| Maks. bevegelighet | 100 m / min | |

| Støttende format | PLT, DXF, BMP, AI | |

| Kraftbehov | 380V / 50Hz | |

| Kjølemåte | Vannkjøling | |

| Arbeidsbar maks. laste | 1000KGS | |

| Overføringsmetode | Ballskrueoverføring | |

| Borddrevet system | Japansk importert servomotor og kjøresystem | |

| Fokusmetode | Følgende og automatisk justere fokus | |

| Kontrollmetode | Frakoblet bevegelseskontroll | |

| Kontrollprogramvare | Perfekt Laser profesjonell laserskjæringsprogramvare | |

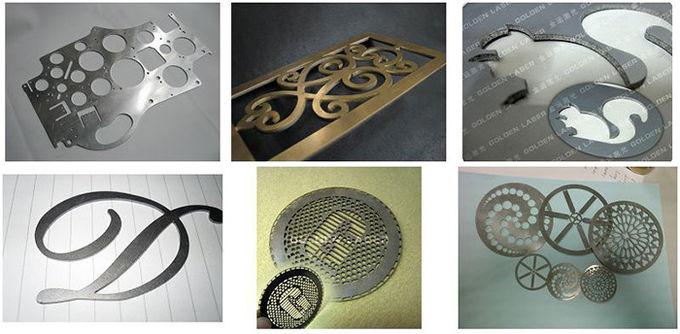

Applikasjon og prøve

Brukes i metallbearbeiding, luftfart, romfart, elektronikk, elektriske apparater, t-banedeler, bil

maskineri, presisjonskomponenter, skip, metallurgisk utstyr, heis, husholdningsapparater, gaver og håndverk,

verktøy behandlingen, utsmykning, reklame, metall utenlandsk behandling en rekke ma

Alternativ for laserkilde

Raycus: 500W, 750W, 1000W, 1500W,2200W,3300W,4400W

IPG: 500W, 700W, 1000W, 1500W, 2000W, 3000W, 4000W,

Ulik laserkraft på grunn av forskjellig laserskjæretykkelse, materialer og produksjonsmengde.

Installasjon

Etter at maskinen når kjøperens nettsted, er ingeniørene fra selgeren ansvarlige for maskininstallasjonen

og igangkjøring ved bruk av spesialverktøy under hjelp av kjøper. Kjøper bør betale for ingeniøren vår

visumavgift, flybilletter, overnatting, måltider mm.

Den vanlige beskyttelseskunnskapen om lasersikkerhet

Det grunnleggende prinsippet for lasermodul og strukturen til laserskjæremaskin

Driftsferdighetene til fiberlaserskjæremaskin

Utstyrsdrift og søknadsmeldingen

Ferdigheter til utstyr daglig vedlikehold, justering av lasermodul og utskifting av reservedeler.

Installasjons- og treningstiden er ca. 5 til 7 dager.

Garanti og service

1). 1 års garanti for hele maskinen

2). 2 års garanti for fiberlaserkilden

3). Livslangt vedlikehold

4). I garantiperioden, hvis det går i stykker eller noen deler er skadet (unntatt de menneskelige faktorene og faktorene

av force majeure), selgeren bør være ansvarlig for reparasjon gratis, delene som må byttes ut vil være

levert fra selgeren gratis (unntatt hurtigslitasjedelen).

5). Etter at garantiperioden har utløpt, trenger kjøperen bare å betale de faktiske vedlikeholdskostnadene.

6). Noen kunder, vi vil betale et returbesøk for flere ganger ett år, og vil gi teknisk støtte

service når som helst, og lever også reservedeler når som helst kjøperen ønsker.

7). Responstid etter salgsservice: rask respons innen 8 arbeidstimer, etter mottak av reparasjonsanropet,

vår ettersalgsingeniør vil svare så snart som mulig.