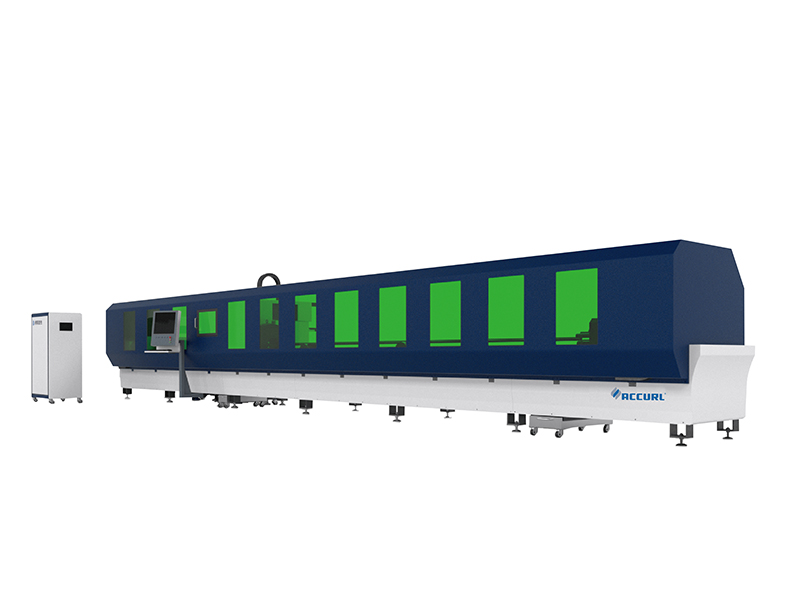

1.The laser maskin both can engraving & cutting,and more functions,widely uesed.

2.Adopt integrated,stable and reliable design framework.

3.All models adoptimported components,ensure the high accuracy,faster speed and longer using life.

4.According to process different materials,can optional knife strip stable,honeycomb table and flat table.

5.the materials can through the laser machine front and rear,materials lenths is unlimited.

6.LCD controlling panel support various languages and clear display,more convenient operation.

7.Combined with the sophisticated technique computer control,precision machinery,DSP digital control technology,USB data transmission and other high-tech.

| Modell | ACCURL-1325 / 1530 / 2030 |

| Engraving and Cutting Area | 1300*2500/1500*3000/2000*3000mm |

| Tube type | CO2 sealed glass laser tube |

| Laser wave | 10.6um |

| Laserkraft | 40w/60w/80w/100w/130w/150w |

| control laser power | 0-100% software settings |

| Cooling type | Vannkjøling |

| Engraving Speed | 0-75,000mm/min |

| Klippehastighet | 0-40 000 mm/min |

| Reposisjonens nøyaktighet | 0.01mm |

| Minimum Character Size | English:1mm*1mm ; Arabic numbers:1mm*1mm |

| Vedtak | 4,000 DPI |

| File output mode | 2.0 USB interface |

| Maktkraft | <2,000W |

| separations cutting | yes |

| Støtteformat | PLT,DST,DXF,DWG.CDR, AI etc |

| Støtteprogramvare | Coreldraw, Photoshop, Auto CAD etc |

| Working Environment Temperature | 0-45C,5%-95% free of condensed water |

| Kontrollsystem | DSP offline control system |

| Arbeidsspenning | 220V,50HZ/60HZ |

| Pakke | kryssfinerkasse |

CO2 laser engraver and cutter is widely used in many kinds of industries, like Advertising industry, Carved gifts and crafts industry, Packing and printing industry, Leather clothing industry, Architectural model industry, Production totem industry, etc.

The laser industry is booming, and is also widely used in the electrical industry.

Laser cutting machine mainly used for the installation of electrical equipment components for processing of sheet steel parts. Laser cutting, greatly improve product quality, reduce production costs, reduce labor intensity,

improve the traditional plate processing technology, and receive better benefits.

Laserskjæremaskin has the following advantages:

1. The laser cutting machine is to use a laser whic has a high power and density characteristics to do the

processing energy. The singlemode laser beam was greatly increased through focused power density.

Because the focused spot diameter is small that the cutting accuracy is higher than relative other traditional cutting machine.

2. Traditional blanking, cutting angle, openings and trimming process is relatively backward,

directly affect the product quality and production costs.

3. Traditional punch processing requires a lot of molds, electrical parts hole size and shapes,

one-piece and a particularly large number of non-standard products.

The mold of the high cost, long production cycle, is not conducive to a single piece, and the production of non-standard parts.

4 using portable curve sawing opening, not only cutting of poor quality,

the dimensional accuracy is difficult to control, and high labor intensity, noise,

and low production efficiency, and low efficiency of the production of road consuming multi Saw.

In addition to the electrical industry, laserskjæremaskin are also widely used in other industries, such as:

advertising production industry, sheet metal processing industry, machining industry, stainless steel decoration

industry, handicraft industry, automobile manufacturing and so on.

Grunnleggende informasjon

Model NO.: ACCURL-1325

Controlling Mode: CNC

Milling Cutter Diameter: 4mm

Certification: CCC, ISO9001, CE

Tilpasset: Tilpasset

Laser Tube Power: 200-350W

Driver and Motor: Leadshine, Panasonic

Transport Package: Plywood Case

Opprinnelse: Kina

Carving Material: Stainless Steel

Main Axle Rotational Speed: ≤24000rpm

Feeding Height: 300mm

Garanti: 24 måneder

Tilstand: Ny

Retail Countries: European, Arab, Us, and Other South North America

Varemerke: ACCURL

Specification: ACCURL-1325

HS Code: 8479899990